In the quest to improve the sustainability of product packaging, the primary focus has thus far been on recyclability. How can packaging be more easily recycled? How do we guide consumers to recycle properly?

Recycling rates of aluminum, glass and paper are heartening. However, recycling alone is not the answer, particularly for plastic packaging. In 2021, only 4.7% of plastic household waste was recycled.

That’s why it’s critical we don’t ignore the other two Rs: reduce and reuse.

The first of these is reduction. Waste reduction focuses on eliminating single-use material at its source. The benefits of such reduction are twofold: (1) reduced material and shipping costs and (2) a lower environmental footprint.

Reduction opportunities span primary, secondary and tertiary packaging.

Right-sizing

One approach is beautiful in its simplicity – right sizing primary and secondary packaging to avoid wasted space. It is estimated that the average shipping carton is 40-60% empty space, resulting in excess material used in the carton itself and in void fill to protect products.

Material reduction is often as simple as ensuring a snug fit: through the application of on-demand packaging technology, a parts distributor reduced average box size by 40% and void fill usage by 60%. Likewise, a major hard goods retailer was able to reduce material usage by over 8-12% simply by making small reductions in the size of their primary packaging with no changes to the product itself.

Efficient use of space

An area of unexpected savings can be found by simply tweaking the shape of primary packaging to eliminate wasted space during shipping. Odd angles and circular designs may create impact at shelf and optimize primary package volume, but they lead to unused space when packed onto pallets and shipped to stores.

The efficiency gains can be surprising. A major margarine brand moved away from its traditional circular tub to a rectangular one that could be more tightly packed during transportation. The result was a 3% decrease in plastic use, primarily in tertiary packaging that consumers never see.

Material substitution

Single-use plastic has become ubiquitous for a variety of reasons: its low cost and its adaptability two among them. It also significantly enhances shelf life of perishable products.

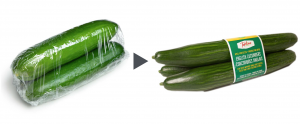

What happens if we find natural products that fulfill the same function? Materials science is discovering novel methods to protect products using natural materials. One example, Apeel, applies a breathable layer of edible plant oils to the outer skin of fruits and vegetables, eliminating the need for cling wrap such as that found protecting English cucumbers.

Product reengineering

Packaging design is dictated by the nature of the product inside. As a result, products can be reengineered to change the needs placed on primary and secondary packaging.

Cleaning products have witnessed such an evolution. Laundry detergent, as an example, has historically contained 60-90% water. Ever-increasing concentration of laundry detergents have reduced the volume of packaging required for each load of laundry. However, new laundry detergent sheets have eliminated the challenge of containing and shipping liquids altogether, allowing primary packaging to shift to much smaller paperboard packages that are significantly easier to recycle. Similar reengineered products include toothpaste tabs, solid shampoos and powdered household cleaners.

Contact us today.

bryan@therealfish.agency